Description

The construction of this machine is based on the standard BS855,1992 which is under supervision and inspection of the Standards Institute as well as the NAZERKARAN inspection company, which is subjected to a number of quality control, testing and quality tests, and is issued to the customers and at the end the consumed items license and certificate honorably will be presented to customers.

Used steels in the manufacture of pressurized areas is of, 17 MN4 or A516Gr (70) type. Boiler tubes are standard according to A106 or ST35 / 8. The boilers body insulation is of ceramic insulation or rock wool with suitable density and its final is of stainless steel sheet. These boilers are in the form of a 3-pas firewall WET-BACK & DRY-BACK .

All designing and construction operations are carried out under the supervision of the NAZERKARAN Inspections, and the standard license-plaque is issued by this company and are installed on the boiler. All welding wires are according standard, under radiographic and ultrasonic tests, and boilers are subjected to a hydrostatic test at a pressure of 1.5 bar more than the designing pressure.

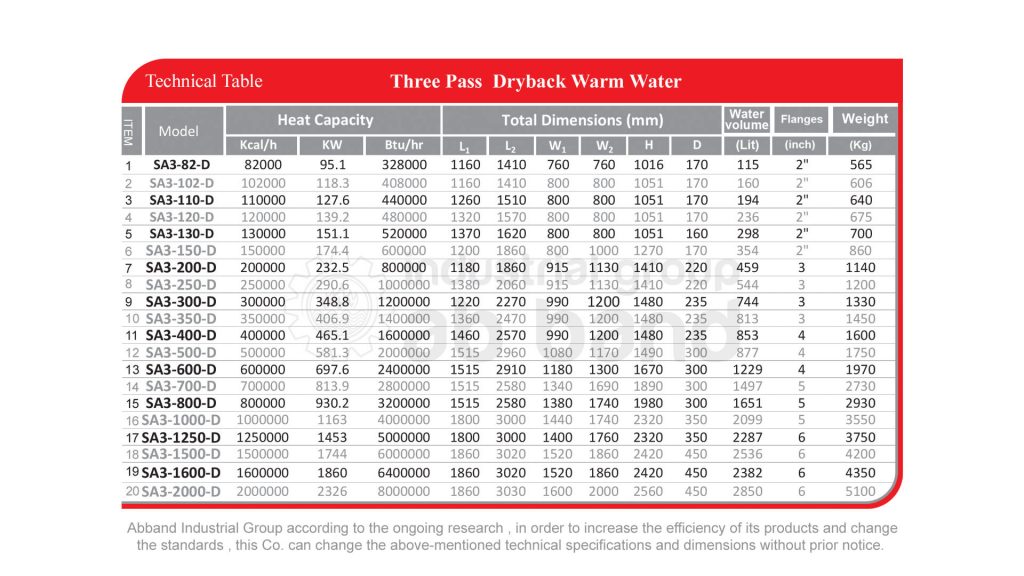

The welding of pressurized parts is done automatically by the SAW method, which provides the highest quality of welding and integrity. The used electrodes for intrusion and supplementation are 6010 and 7018, which are used according to WPS and PQR. All used flanges are of class 150 and 300 type. These boilers have a working pressure of 6 bar, and the ability to provide maximum allowed water temperature. The actual capacity of produced boilers of this group are from 82,000 kcal / hr to 8,000,000 kcal / hr.

Reviews

There are no reviews yet.